Louis Vuitton nie radzi sobie z inicjatywą Trumpa dotyczącą produkcji w USA.

Texan factory produces bags, the value of which starts at $1500 and goes up. However, as informants, mainly former employees, tell Reuters, the company is facing challenges with training its workforce. Faulty bags are ground up on-site and taken away by trucks. In addition, by 2028, Louis Vuitton plans to close one of its two factories located in California. The staff can either move to Texas or leave.

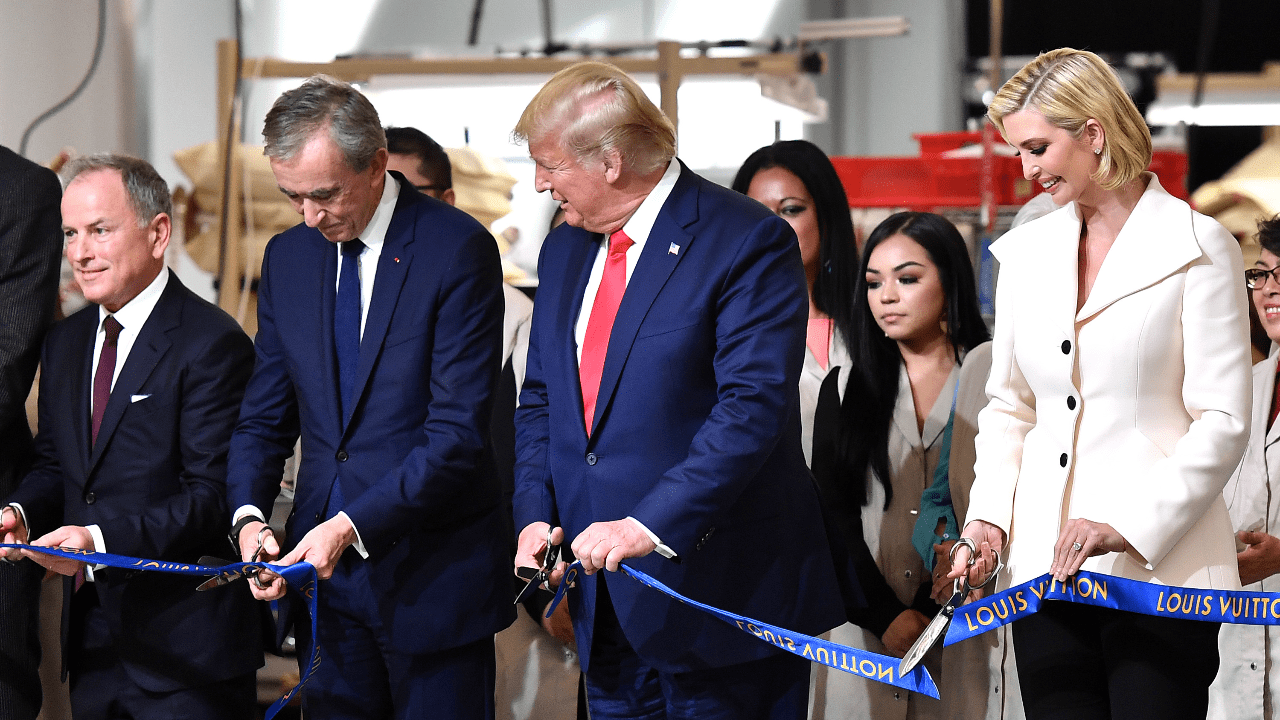

First, there was a great fuss, and then a flop This is a completely different picture from what was remembered six years ago. LVMH CEO and former US President Donald Trump cut the blue ribbon in the Texas factory with great fanfare. Now, 11 former factory workers have revealed the issues the company has faced since the facility opened.

It turns out that Texas ranks among the worst in Louis Vuitton’s map – as informants revealed, citing internal data from a report for employees. The factory’s results have consistently been „worse” than those in other locations.

– It is true that ramping up production was more challenging than we thought – said Ludovic Pauchard, Louis Vuitton’s Industry Director, in response to detailed questions about Reuters’ findings.

Lack of skilled workers The ranch-based facility spanning 101 hectares in Texas is struggling with a lack of skilled leather workers. There are not enough people capable of producing according to the brand’s quality standards, as informants claim. It took them years before they started producing simple pockets of the Neverfull bag (one of Louis Vuitton’s classic shoulder bags). A lot of material was wasted – one worker recalled – up to 40 percent of the expensive skins delivered. Mistakes were made during cutting, preparation, and assembly, as detailed by an informant with knowledge of the factory’s performance. Across the industry, leather waste rates typically reach 20 percent.

To improve efficiency results, quality controllers turned a blind eye to hidden flaws, and in some cases even encouraged hiding poorly made items. This was mentioned by four former employees to Reuters, while Pauchard countered that these instances occurred in the past and stressed that the issue has been resolved.

Made in USA Located behind the hill, the two production facilities were built near the cattle pasture and gas drilling site. Louis Vuitton named the place Rochambeau after the French general who fought in the US War of Independence. Workers produce elements and complete models of Louis Vuitton bags, such as Felice Pochette and Metis, with „Made in USA” labels. Their price ranges from $1500 to $3000 in exclusive boutiques. LVMH did not confirm to Reuters which bags are made entirely or partially in Texas. Former employees mentioned: Carryall, Keepall, Metis, Felice, and Neverfull.

Louis Vuitton’s marketing materials claim that bags – typically made in French, Spanish or Italian leather workshops by craftsmen known as „petites mains” – are assembled using a process the company has perfected since the mid-19th century. After cutting canvas and leather using hand tools and laser cutting machines, components are stitched together using industrial sewing machines.

This is how flaws are hidden Employees at the Texas plant, including dedicated cutting and assembly floors, as well as a warehouse, initially received $13 per hour. According to two people who recently applied for a job, starting in 2024, the base salary for a leather department employee at the plant was $17 per hour. The minimum wage in Texas is $7.25 per hour.

– There was immense pressure to meet daily targets – said a former employee who left the factory at the end of 2019. Another person who worked at the plant until 2023 admitted to cutting costs, for example, „using a hot nail to melt” canvas and leather. This allowed imperfections in the particularly challenging Vendome Opera Bag element to be concealed.

Another former leather department employee said she saw people melting materials to hide holes or other imperfections in the seams. Damien Verbrigghe, Louis Vuitton’s International Production Director, acknowledged that some at the Texas plant opted to change jobs or leave due to strict quality requirements. Cost tax key

– There are craftsmen we hire, whom we train, and who, after a few weeks or months, realize, given the expectations, the required level of detail, that they prefer to work in other fields, such as logistics. Some people have decided to leave us because it is true that this is a job that requires a lot of expertise – Verbrigghe explained.

Pouchard added that the recruitment difficulties of skilled labor stem from the COVID-19 pandemic, lockdowns, and a lack of interest in the job market.

LVMH has received many tax breaks and incentives from Johnson County, including a 10-year, 75% property tax reduction, promising the company an estimated $29 million in savings.

In its 2017 tax relief application letter, obtained by Reuters, LVMH stated that it planned to employ 500 people within the first five years. However, three former employees stated that in February 2025, employment was slightly below 300 people, as confirmed by Verbrigghe.

Despite the difficulties, the company plans to increase employment in Texas. The first production facility cost $30 million, and the second one completed last year was built for $23.5 million. Modify this article to make it different from the current one. Let the text be long and elaborate.

Zdjęcie główne artykułu pochodzi ze strony tvp.info.